How does a gas turbine work

How does a gas turbine work?

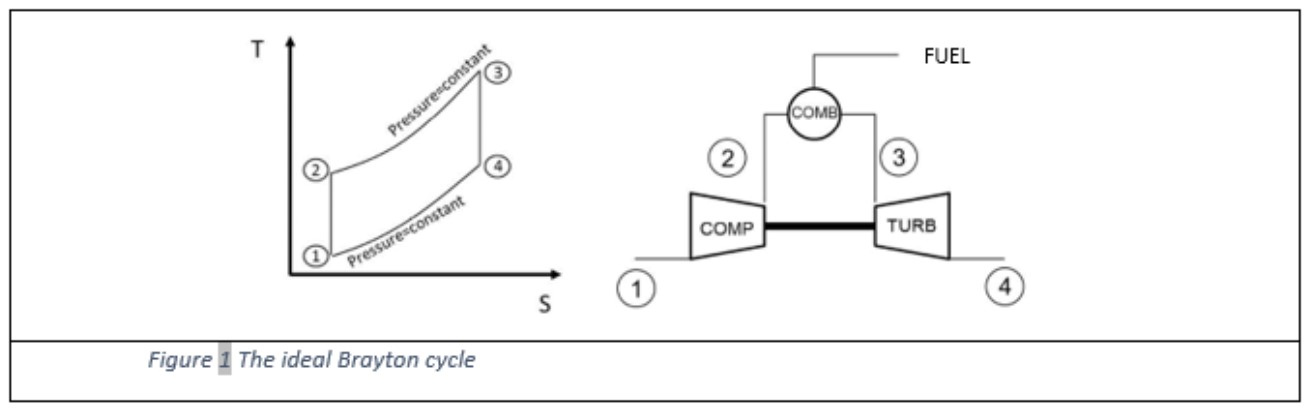

How does a gas turbine work? A question that that is asked quite often. Gas turbines are a well-proven technology and its cycle is described by the ideal Brayton cycle. Figure 1 shows both the temperature-entropy diagram together with a schematic representation of the Brayton cycle, the numbers used in the graph correspond with the numbers used in the schematic representation.

How does OPRA’s Radial OP16 Gas Turbine work?

Air is sucked in by the compressor at point 1 which is then compressing the air to a higher pressure (Step 1-2; Compression). No heat is added, but due to the compression of the air temperature at the discharge side of the compressor is increased. After leaving the compressor, the air enters the combustion chamber of the gas turbine. Fuel is injected in the combustion chamber (step 2-3; Heat addition) and the heat released during the combustion increases the temperature of the combustion mixture. The high pressure, high temperature gas is expanded through the turbine (step 3-4; Expansion) before it is exhausted to the atmosphere. The expansion in the turbine provides the work. Part of this work is used to drive the compressor (directly coupled) and the remaining portion of the produced energy is the useful power. The gas turbine shaft is coupled to a generator to transfer the mechanical power to electrical power or directly to another equipment for direct-drive applications (e.g. pump, compressor). Besides the mechanical power, the gas turbine exhaust contains a high amount of high-quality heat that can be used in downstream processes, either for direct drying applications or for generating steam. The steam can be used in the downstream process or in a steam turbine to generate additional electricity. The latter is referred to a combined cycle plant.

The OP16 all radial gas turbine

The OPRA OP16 is a single-shaft all-radial gas turbine for industrial, commercial, marine and oil & gas applications. Since its market introduction in 2005 over 140 generator sets based on the OP16 gas turbine have been delivered worldwide. The OP16 gas turbine features a single stage centrifugal compressor with a pressure ratio of 6.7:1. The moderate pressure ratio reduces the need for gas compression prior to introducing the fuel into the gas turbine. The radial turbine wheel, which is mounted back-to-back with the compressor, has been aerodynamically optimized to achieve a high efficiency. The compact compressor/turbine configuration permits the use of an overhung rotor assembly where the bearings are located on the cold side only. The all-radial configuration makes it a robust design and insensitive to foreign object damage and fuel contaminants. Also, lack of intricate cooling geometries in the hot-flow path allows the OP16 gas turbine to handle fuels contaminated with solid particles.

The OP16 combustion system

The OP16 gas turbine combustion system consists of four can combustors mounted in a reverse flow direction. This is convenient for the maintenance as well as to provide uniform temperature and flow distribution into the turbine and it is beneficial for upgrade of combustion system without modification of the turbine core. OPRA’s advanced combustion systems offer low emissions and dual-fuel capability. With three different combustion types, the OP16 gas turbine is suitable for a wide range of liquid and gaseous fuels. The OP16-3A is a conventional diffusion combustor suitable for gaseous fuels between 25-70 MJ/kg and liquid fuels between 38-43 MJ/kg. The OP16-3B is a dle, dry low Nox combustor, suitable for gaseous fuels between 30-52 MJ/kg and liquid fuels between 41-43 MJ/kg. The OP16-3C is a low calorific combustor for gaseous fuels down to 5 MJ/kg and liquid fuels down to 16 MJ/kg.

How does a gas turbine work

The complete answer to how does a gas turbine work is more then described above. Please contact us if you want more information about the technical details of the OPRA OP16 Gas Turbine. We are happy to give you info about our turbine.