Biomass can be converted into liquid or gaseous fuels (Biogas). The high fuel flexibility of the OPRA OP16 Gas Turbine allows for utilization of low-calorific fuels even if the composition is fluctuating over time.

Turn Your

Waste Gases

Into Power

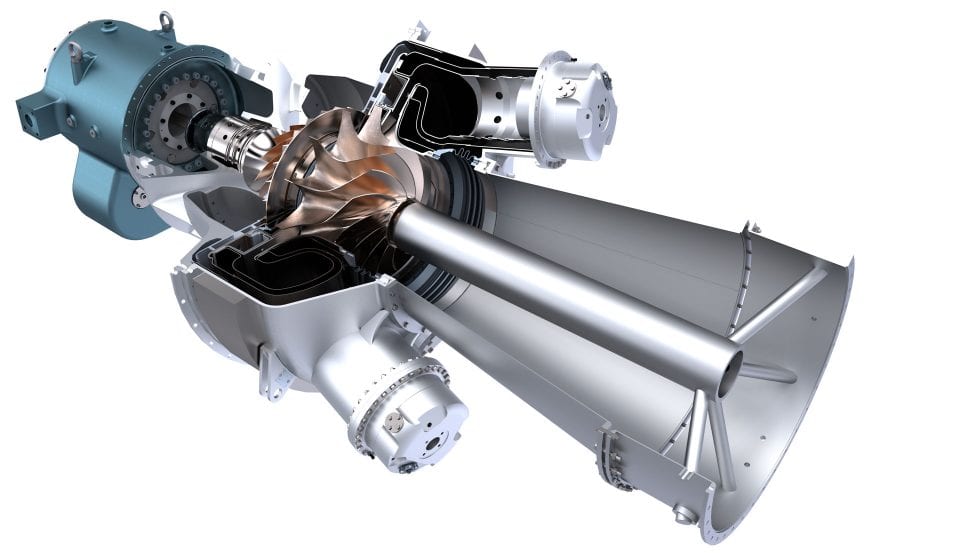

The OPRA OP16 Gas Turbine enables...

- Use of ultra low-calorific, contaminated fuels e.g. syngas, biofuels

- Excellent solution for decentralized Waste to Power

- Low maintenance cost

- High hydrogen content in fuel accepted

The OPRA OP16 can handle your gasified or liquefied waste as fuel

Destinus Energy expertise

To ease the process of integrating the OPRA OP16 Gas Turbine into your current or new application, we can assist by providing process know-how and knowledge of best practice. Are you looking for a turnkey solution? We work with an international network of Oil & Gas partners who are experts in integrating our equipment into existing or new plants.

The OPRA OP16 Gas Turbine creates value in your application!

The high fuel flexibility of the OPRA OP16 Gas Turbine allows for utilization of low calorific fuels even if the composition is fluctuating over time. Synthetic gases of different compositions can be utilized as fuel!

The high fuel flexibility of the OPRA OP16 Gas Turbine allows for utilization of low-calorific liquid fuels even if the composition is fluctuating over time.

In many cases off-gases or tail gases are produced as a byproduct of industrial and chemical processes. The OPRA OP16 Gas Turbine can use even these challenging gases as fuel generating heat, steam and electricity to feed back into the process.

Ammonia processes typically produce a low-calorific tail gas which is often flared or simply combusted in a boiler. The OPRA OP16 Gas Turbine can utilize this gas to generate heat and electricity to feed back into the ammonia process.

Fertilizer plants require large amounts of heat, steam and electricity in their processes. In many cases off-gases are produced as a byproduct of fertilizer operations. The OPRA OP16 Gas Turbine can use even these challenging gases as fuel generating heat, steam and electricity to feed back into the process.

Whenever crude oil is stored in large containers, certain components “gas out” and form VOCs (Volatile Organic Compounds), which need to be removed from the tank. Instead of flaring these VOCs, Destinus Energy can utilize VOCs as a valuable fuel.

The high fuel flexibility of the OPRA OP16 Gas Turbine allows for utilization of low-calorific fuels even if the composition is fluctuating over time. Landfill gases of different compositions can be utilized as fuel in the OPRA OP16 Gas Turbine!

What people ask for the most

There are different methods to gasify organic waste. Biodigestion, pyrolysis, or plasma gasification are just some examples. The low-calorific gases produced by these processes can be utilized in the OPRA OP16 Gas Turbine.

To ease the process of integrating the OPRA OP16 Gas Turbine into your current or new application we can assist you by providing process knowhow and knowledge of best practice. Are you looking for a turnkey solution? Destinus Energy works with an international network of partners and technology owners who are experts in integrating our equipment into existing or new plants.

Any types of organic waste in liquid or solid form can be transformed into liquid and gaseous fuels. Check out our gas composition checker for more details on what fuels we can handle!

Off-gases, which are a byproduct of downstream processes, often contain high amounts of hydrogen or have a low calorific value, which often fluctuates over time. The OPRA OP16 Gas Turbine can use even these challenging gases directly to generate clean electricity without the need for cleaning.

Opra Turbines is now part of Destinus

Dear visitor,

We would like to inform you that OPRA has been acquired by Destinus SA on Wednesday 12th April 2023. As part of this transition, the OPRA company name will be changed to Destinus Energy.

The OPRA OP16 product name will remain unchanged and will continue to be used to identify our gas turbine products in the oil & gas, industrial & commercial, waste to energy and marine VOC destruction markets.